Expanding the Refrigerated Footprint with 3PL Services

De Pere, Wisconsin USA Site Visit

October 10, 2011

By

Kurt Baumann

Management:

Bruce Tielens, President and Chief Executive Officer

Greg Bredael, Chief Financial Officer

Randy Tielens, Executive Vice President

Dan Wallace, Director of Transportation and Operations

Establishing a Presence in Food & Beverage

WEL Companies started out as an asset based refrigerated trucking company in 1975 based in De Pere, Wisconsin. It provides truckload (TL) long haul, and regional, less-than-truckload (LTL) services throughout the lower 48 states, specializing in temperature-controlled and dry freight transportation. WEL has established a strong presence in the Food & Beverage vertical industry with a long list of marquee customers that includes some of the largest food companies in the U.S. and world as well as many mid-sized and small food companies. While the majority of WEL’s trucking services are common carriage, it also provides dedicated contract carriage to customers.

The original owners, Bruce Tielens, president and chief executive officer, and Randy Tielens, executive vice president, have long since traded their tractor cabs for corner offices, but remain actively engaged in managing the business. The Tielens established a core set of tenets that have been the driving force behind the business of establishing long-term partnerships with customers, providing high quality and reliable service, and finding innovative solutions to their customers’ logistics needs. WEL’s success is evident in the company’s continuous annual growth and expansion of value-added services. WEL Companies’ top line revenue grew by 14% in 2010 to $171 million. Net revenue increased by 16.2% with an operating ratio of 96.4%. Growth service areas include:

- Refrigerated Trucking (TL, LTL and Dedicated)

- Box Car Trans-loading

- Container Stripping and Drayage

- Freight Brokerage

- Reverse Logistics

- Nationwide Temperature-controlled and Dry Warehousing

- Cheese Storage (Aging), Financing and Processing

Building on a Base of Core Refrigerated Trucking Operations

WEL Companies’ fleet started with two trucks and has expanded by a compound annual growth rate (CAGR) of 17% since 1975 to 550 units, which it owns. Since the economic downturn in 2008, most carriers broadly pulled back on new equipment purchases. Yet, WEL continued to invest in its fleet. WEL’s fleet is young and well-maintained with an average age of three years, against a trucking industry average of 6.7 years. It also owns 824 refrigerated trailers with an average age of four years.

WEL Companies’ core industry segment, Food & Beverage, continues to benefit from the increasing trend in consumer preference for fresh and frozen, prepared foods. A&A estimates that U.S. third-party logistics (3PL) market revenues from this segment grew by 19% in 2010 to $9.9 billion, which excludes trucking revenue. Likewise, WEL Companies benefits from this growth, as a critical link in the food supply chain.

Fleet operations are centralized and based in the De Pere, Wisconsin headquarters building. WEL has a team of 40 customer service and driver manager resources to book loads, schedule appointments, dispatch loads and coordinate drivers. The core fleet management system is TMW System’s Innovative TMS with full EDI (electronic data interchange) capabilities. Tight control of shipment planning and tracking has allowed WEL to hold empty miles to 14%. Customers can access order and shipment tracking information through a web portal.

With 531 company drivers and 27 owner-operators, WEL works hard to make its drivers productive and get them home frequently by leveraging a team of 10 driver managers who work directly with drivers and coordinate with customer service. Consequently, driver turnover has decreased from 80% in 2005 to 50% last year, noting that the industry average in 2009 was 115%. WEL drivers haul 250 loads per day with On-time Pickup and Delivery of 98%. WEL’s Damage Free Transit ratio has ranged from 0.08% to 0.25% of revenue since 2006. Currently, 70% of the loads are TL and 30% are LTL. Only 5% of WEL’s trucking volume is dry van. WEL Trucking maintains a “satisfactory” rating (best possible rating) from the DOT (U.S. Department of Transportation) and an ISS (Injury Severity Score) of 25 (below 50 is ideal).

As one would expect from a top-notch carrier, WEL is a SmartWay™ Transport Partner. Having implemented recommended practices in 2007, WEL receives high marks (score of 1.25) for its efforts to minimize both fuel consumption and emissions. All fleet equipment is outfitted with idle APU (auxiliary power unit) reduction technology. In 2008, WEL purchased 70 engines with ULSD (ultra-low sulfur diesel) fuel, producing lower emissions.

Building on a Base of Core Refrigerated Trucking Operations: WEL Freight Brokerage

Freight Brokerage was an out-growth of its trucking operation. WEL Trucking shifts excess or out of network demand to its Freight Brokerage division to source additional capacity. WEL leverages its access to refrigerated capacity with a growing base of 100 carriers. This division handles 20 to 25 loads per day, which generated $10.5 million in gross revenue in 2010 with an operating margin of 15%.

While this division grew from opportunity, WEL recognizes the potential for both top line revenue growth and bottom line margin contribution from this business and is shifting greater emphasis and resources into its expansion.

From Cross-docks and Cheese Storage: WEL Warehousing

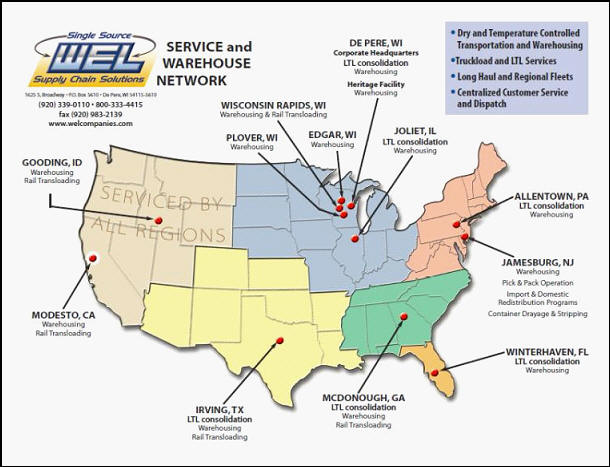

Expanding from its Midwest base, WEL Companies has developed a nationwide footprint for refrigerated warehousing with 16 facilities in nine states and 1.3 million square feet under roof. About 60% of the warehouses are owned and 40% are leased. All of the warehouses are food grade and AIB (American Institute of Baking) certified with combinations of cooler, freezer and dry storage space. Cooler and freezer space comprises 42% of the total and dry storage is 40% with the remaining 18% of space taken up by docks, utilities and offices. WEL has a physical presence in the major geographic food distribution centers. Most of the facilities primarily function as LTL consolidation centers, such as Allentown, PA; McDonough, GA; Winter Haven, FL; Irving, TX and Modesto, CA. Many of them have expanded to include services such as pick and pack, cold storage and trans-loading, such as Joliet, IL; Jamesburg, NJ and De Pere, WI. About 40% of WEL’s facilities have direct rail access.

WEL Companies implemented the LogiMax warehouse management system (WMS) to manage cross-docking, pick/pack and inventory management. LogiMax is a browser-based system designed for 3PL warehouses that provides multi-customer and inventory control with integrated RF (radio frequency) data collection, third-party billing, report writing and customer web self-service. It’s a mid-market system with functionality that includes:

- Automatic queuing of fulfillment orders based on inbound carriers;

- Advanced put-away logic that recognizes velocity, stackability, date mixing rules, and maximizes space and cube utilization;

- Real-time data on unexpected or time-critical deliveries that require attention;

- Automatic generation of compliant labels for ready-to-stage pallets;

- Direct pallet building for split-case and case picks based on item crushability;

- Replenish interleaved forward pick locations;

- Automatic order sorting by requested ship date;

- Employee productivity monitoring using time standards;

- Automatic enforcement of product consolidation, rotation and location rules;

- Elimination of paper from the entire warehouse; and

- Order checking and loading tasks which ensures order and load integrity and provides detailed loading diagrams.

WEL Companies works with a number of cheese producers, such as Great Lakes Cheese, BelGioioso, Schreiber and Churney Cheese. For cheese companies, WEL offers specialized services to support cheese aging, financing, shredding, and packaging. Each type of cheese has specific aging requirements that require temperature-controlled storage in specialized reusable containers and periodic testing. Recognizing the customer need, WEL establishing a Cheese Financing business to purchase cheese from producers, store it and then re-sell it in bulk or packaged form, using outsourced cutting/shredding and packaging services.

Growing 3PL Services

The Tielens picked the right industry segment to establish a trucking and 3PL services business. Despite the challenges of a tough economy and downward pressure on freight rates, WEL Companies has benefited from its emphasis on serving the Food & Beverage industry. WEL’s top line revenue continues to increase. While freight rates continue to improve with increasing demand and tightening carrier capacity, WEL is also benefiting from its expansion of 3PL services for both value-added warehousing and freight brokerage services. Holding true to its core tenets of long-term customer relationship building, high service performance and innovative logistics solutions, WEL is well-positioned for continued growth and profitability.