Ryder Dedicated Services – All Shades

Orlando, Florida USA Site Visit

September 21, 2017

By

Richard Armstrong

Participants:

Ryan Martin, Director of Customer Logistics

Jimmy Meadows, Director of Business Development

John DeAngelo, Vice President of Business Development

Michael Woods, Director of Distribution

Ryder provides dedicated services to a major paint manufacturer throughout the United States and Canada. The partnership began more than 40 years ago when Ryder began providing equipment and maintenance services to the paint manufacturer’s locations throughout the United States. The partnership expanded in 2015 when Ryder launched dedicated services for a new distribution center located in the Northeast. Through the longstanding partnership, Ryder now provides Dedicated Transportation Solutions including 61 tractors, 61 trailers, and 61 drivers to 10 of the manufacturer’s locations in the United States and Canada. One of these facilities is a 78,000 square foot warehouse in Orlando, Florida.

The operation in Orlando is a high-quality partnership between Ryder and the paint manufacturer. It was established seven years ago when the paint manufacturer restructured. Ryder uses its TranSync software to optimize the daily network between for-hire carriers and its dedicated fleet. The fleet operates throughout Florida with 95% of deliveries being same day. Ryder tractors all have electronic logging and safe driver cameras.

The TranSync tool was developed to replace the normal private fleet management system based on spreadsheets. TranSync analyzes the best combination of modes at the lowest network cost, in real time, load by load, every day. Available drivers, fixed fleet costs and backhauls are part of the calculations. A user needs $10 million or more in cost per year to get the best use of TranSync.

Ryder also implemented its new neutral integration platform, RyderShare, to improve visibility, tracking, and business intelligence for the paint

manufacturer’s deliveries.

The paint manufacturer has ~1,900 employees with seasonal variations covered by temporary workers. Order sizes vary daily from less-than-truckload (LTL) to truckload (TL). The average order is 10 lines and 50 gallons. The warehouse is managed using Manhattan’s WMS (warehouse management system). The warehouse has 32′ clearances.

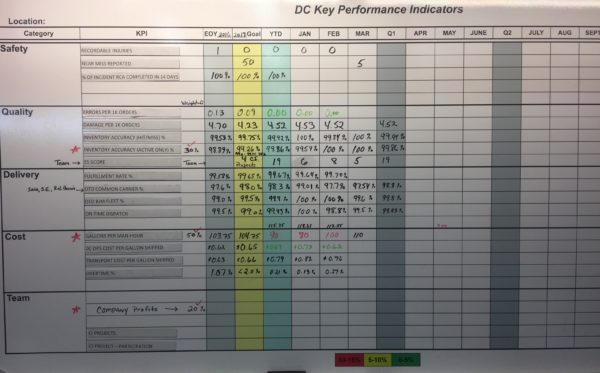

The paint manufacturer emphasizes five areas for key performance indicators (KPIs): Safety, Quality, Delivery, Cost and Team. Quality is built around Errors per 1,000 Orders, Inventory Accuracy, and Scores for the team as a group. Delivery uses Fulfillment Rate, On-time Delivery for the paint manufacturer’s fleet and common carriers, and On-time Dispatch. Cost is measured in Gallons per Man Hour, DC Cost per Gallon Shipped, Transport Cost per Gallon Shipped, and Overtime.