Sataria Group Targets Food Industry Customers for Growth

Indianapolis, Indiana USA Site Visit

November 22, 2010

By

Evan Armstrong

Key Personnel:

Robert Moran, CEO, Sataria Group

Greg Westover, Vice President of Sales & Marketing, Sataria Group

Patrick O’Keefe, Director of Operations, Sataria Distribution

Sataria Group Business Overview

Sataria Group is a food industry niche 3PL made up of Sataria Distribution and Sataria 3PL. It had revenues of $16 million in 2009 and has a staff of just over 90. Sataria Distribution provides value-added warehousing and distribution 3PL services. Its sister company, Sataria 3PL, focuses on providing temperature-controlled domestic transportation management services and has offices in Minneapolis, MN; Las Vegas, NV; Indianapolis, IN, and Chattanooga, TN.

Distribution was acquired by private equity investor Creo Capital Partners in September 2008. Sataria 3PL was established by Creo through a 2009 merger with Midway Distribution, Inc. Creo Capital Partners is a private equity investment company which focuses on middle-market companies involved in the food, food logistics, transportation, and financial services industries through its investment funds.

Sataria Distribution’s main contract value-added warehousing and distribution customer is an international starch manufacturer. Its dedicated Indianapolis, Indiana warehousing operation is detailed below. In addition, Sataria 3PL is managing temperature-controlled transportation for customers in the pharmaceutical, wine and beverages, aerospace and specialty food products industries. These include: Best Brands, General Mills, Heinz USA, Kraft Foods, Snapple, and Tyson Foods.

Dedicated Value-Added Warehousing & Distribution Operation

On the west side of Indianapolis, Sataria Distribution is running a dedicated 600,000 square foot value-added warehousing and distribution operation providing plant support warehousing services to its customer’s local manufacturing operation. The operation began in 2005, has been ISO 9001 certified since May 2007, and operates to AIB (American Institute of Baking) standards. Approximately 65 employees work in the 24 hour, seven day a week, two-shift operation.

The customer uses SAP for its ERP (enterprise resource planning) system and electronically interfaces with Sataria’s Provia WMS (warehouse management system) to transmit orders for picking and shipping and to receive order and inventory information from the WMS. Forklift mounted RF (radio frequency) scanners interface with the WMS and are used to drive and manage warehouse tasks.

Shipments of inbound starch products are received daily from the customer’s Indianapolis manufacturing plant as well as European plants via ocean container. Sataria receiving personnel apply barcodes to all products at receipt, verify product quantities, and scan the product into the WMS. To support any potential recalls, product is also monitored by production lot numbers.

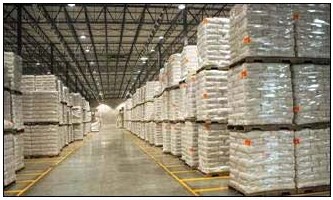

Approximately 500 SKUs (stock keeping units) of product is stored in 3,550 warehouse locations. 80% of the warehouse is bulk storage and 20% is racked. The starch is very dense and heavy weighing 2,250 pounds per pallet. The majority of the starch is packaged in super sacks and bags and most warehouse handling is pallet in and out.

Sataria uses ABC inventory management to position faster moving product closer to the shipping doors. All of the products turn over approximately every six weeks.

The customer’s Indianapolis plant is its largest domestic shipping point. Outbound daily order/shipment volumes range from 15-20 less than truckload (LTL) orders/shipments and 65-100 truckload orders/shipments of product. In addition to its WMS, Sataria uses Provia’s YMS (Yard Management System) for inbound and outbound dock door carrier scheduling and trailer pool management. 35% of outbound product is destined to European Union customers and Sataria is responsible for preparing the export documents.

Inventory management is a key value-added service provided by Sataria. Sataria performs daily directed and undirected cycle counting and has achieved 99.97% inventory accuracy. In addition to inventory accuracy, the operation monitors 19 other operating metrics

Bulk Storage of bagged and palletized starch

Super Sacks of starch in racks

Picking Super Sacks for shipping

as part of its weekly report card. Other operational Key Performance Indicators (KPIs) include: on time average load time, customer complaint rates, damage as a percent of volume handled, and order cycle count accuracy.

Developing Domestic Cold Chain Transportation Network Operations

Sataria Group recently began marketing a cold chain transportation network service for the underserved frozen, refrigerated, and protective service LTL transportation market. It has contracted with a cadre of refrigerated U.S. warehousing providers and transportation providers to create a LTL consolidation and distribution network. The network utilizes five main regional consolidation centers. Sataria 3PL’s four offices and its systems will provide the operational coordination and management. Sataria launched its cold chain transportation service in the third quarter of 2010.

Operations Review Summary

Sataria Group is a small but developing food industry specialist. As it continues to build upon its value-added warehousing and distribution operations and add cold chain LTL transportation management services, we see it offering a fairly unique mix of 3PL services. This niche service offering should spark the interest of many food industry manufacturers and suppliers.