Rinchem Company, Inc.

Glass Pipeline for Global Chemicals Logistics

Albuquerque, New Mexico USA

September 2019

By: Kurt Baumann

Albuquerque, New Mexico USA

September 2019

By: Kurt Baumann

Personnel:

Chris Wright – SVP Operations

Robert Walker – VP Finance and Administration

Troy Brown – VP Sales & Marketing

John Fitzsimmons – VP Operations, Warehousing

Bonnie Clements – VP Operations, Transportation

Sandi Privett – Director Sales Operations & Risk Management

Dustin Miles – Director Global Transportation Office

Andy Sutton – Sales Manager

Dustin Richins – Business Applications Manager

Graham Palmer – Logistics Engineer

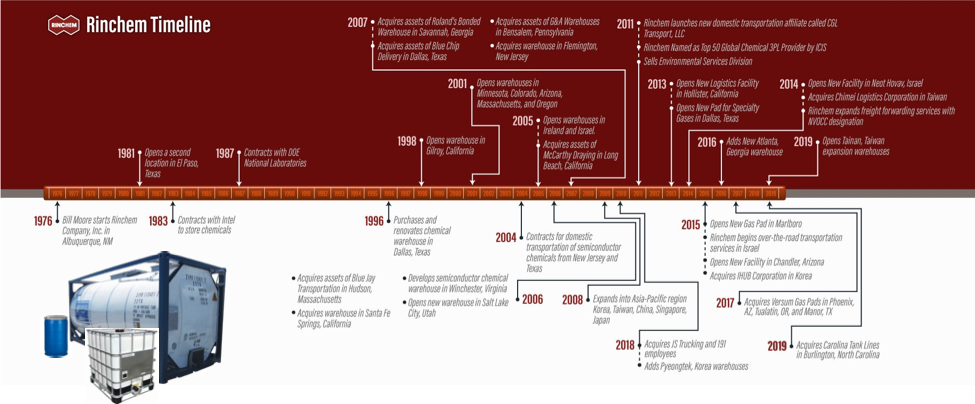

In 1976, Bill Moore established a second location in Albuquerque, NM for an Arizona chemicals distributor and ran the two-person business supplying general chemicals to a variety of industries, including paint and fiberglass manufacturers. Mr. Moore purchased the Albuquerque location in 1983. Over four decades, Rinchem has grown and transformed into a global third-party logistics (3PL) provider with trucking assets and 1,000+ employees providing end-to-end supply chain logistics services with specialization in replenishing chemicals for manufacturing. From the producer to the end-user, Rinchem excels at transporting, storing and handling prepackaged specialty chemicals and gases.

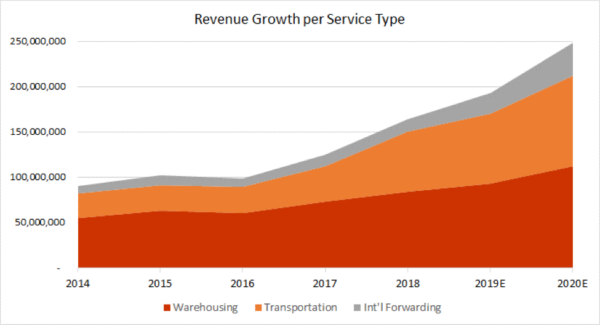

Over the past five years, Rinchem experienced significant revenue growth at a 16.3% compound annual growth rate, driven by a series of facility additions and acquisitions in the United States, Taiwan and Korea.

Fabricator Services: When a finished goods manufacturer needs help to provide chemicals storage and just-in-time (JIT) replenishment to a plant from multiple vendors, Rinchem sets up a warehouse or merges the new customer into a multi-client facility close to the plant, as well as provides a full range of transportation services.

Chemical Producer (or Distributor) Services: When a chemical producer needs help to distribute chemicals to multiple manufacturing customers in a geographic area or position and replenish vendor-managed inventory (VMI), it will store the producer’s chemicals in a Rinchem location that is optimal for its distribution network and required service level. Rinchem’s customers include leading chemical producers such as Dow, KMG and Merck. Since Rinchem does not own or sell chemicals, it is a neutral third-party that allows chemical producer competitors to use Rinchem’s services with confidence.

Both customer types require reverse logistics support to return reusable containers like totes and ISO tanks.

Lead Logistics Provider (LLP): Is the coordination of all logistics related activities and suppliers, including analysis of and recommendations regarding modes of transport, opportunities for consolidation, customer service performance levels and opportunities for improvement of the supply chain.

3PL Value-Added Warehousing & Distribution (VAWD): Provides public or dedicated, temperature-controlled or ambient, regulated or non-regulated warehousing and handling of high purity, pre-packaged chemicals, gases and other materials in ISO 9001:2008 certified warehouses.

3PL Domestic Transportation Management (DTM): Is the intermodal, over-the-road transportation, cross docking or local delivery of wet or dry chemicals in bottles, cases, drums, totes, ISO tanks and specialized containers. Rinchem also provides Freight Audit & Bill Pay services and procurement capabilities, if needed.

Asset-Based Trucking: Rinchem operates a bonded carrier fleet of 333 tractors, 400 specialized trailers and 150 ISO tank chassis for local, 24-hour, JIT delivery, and over-the-road transportation. It has licensed and bonded drayage services to and from the ports of Portland, Los Angeles, Houston, Savannah, Philadelphia, Boston and Newark. Rinchem’s fleet continues to expand with acquisitions such as IHUB and JS Trucking in Korea, Chimei Logistics in Taiwan, and Carolina Tank Lines in the United States.

Rinchem’s fleet is HM-232 (hazardous materials) certified and operates in compliance with federal, state and local laws and regulations.

Safety features include:

In 1983, Rinchem landed a contract with a major semiconductor manufacturer to store and continuously replenish specialty chemicals for making wafers. The Semiconductor industry remains a dominant customer vertical for Rinchem, accounting for 76% of revenue. General commodity manufacturers using chemicals for processing make up the next largest share at 12%. Rinchem’s growth plan includes further development of promising customer industries, including Specialty Gas, Chemical and Life Sciences companies.

Rinchem’s expertise as a premier hazardous cargo logistics provider is applicable across a myriad of industries and diverse transportation requirements. It ships the following classes of materials:

![Screenshot_Pie[2] Screenshot_Pie[2]](https://www.3plogistics.com/wp-content/uploads/2019/09/Screenshot_Pie2-350x200.png)

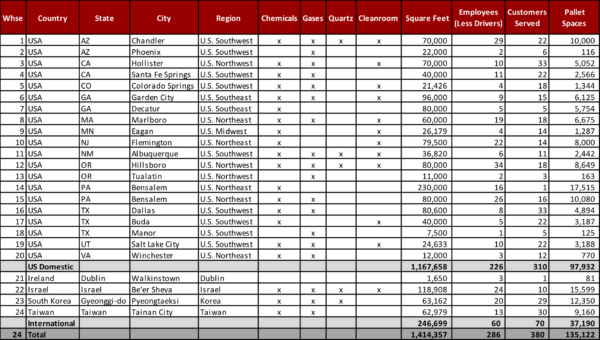

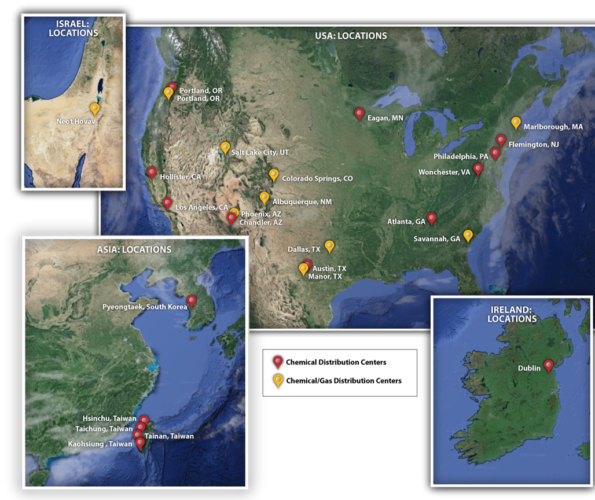

Rinchem operates 1.4 million square feet of temperature-controlled, hazardous materials-compliant warehouse space in a broad network of 24 locations across North America, Europe, the Middle East and Asia. The company operates a fleet of 333 tractors, 400 temperature-controlled, hazmat-customized trailers and 150 ISO tank chassis domiciled at these facilities providing drayage, shuttle and local delivery services.

Warehousing is a core component of Rinchem’s logistics services platform, comprising 48% of revenue. In 2017, the company realized the need to upgrade its warehouse management system (WMS) capabilities as the centerpiece for accurate and timely replenishment of chemicals to manufacturing.

Rinchem realized that the legacy system had reached a practical limit and was not scalable to match the growth rate of the company. Upgrades had become overly complex and resource intensive. It could not accommodate an increasing need to incorporate business rules and required technical modifications, rather than configuration by business users. The legacy system lacked the robust and durable integration methods required as part of Rinchem’s intended digital transformation.

Rinchem conducted a formal WMS selection process based on these criteria and important features, such as:

Rinchem selected Tecsys WMS based on these criteria and initiated a program to implement and rapidly deploy the system across 24 sites with four of them overseas. It partnered with Tecsys to implement five facilities based on unique product storage and handling requirements. During these initial implementations, Rinchem established an internal team with operational expertise to learn the technical skills from Tecsys required to roll-out the WMS across the network. In 2018, 16 warehouses were successfully deployed. This expedited schedule was critical to standardizing operational processes, integrating with key customers, and providing enhanced visibility in the supply chain.

With all sites utilizing the upgraded WMS, Rinchem has been able to improve safety, accuracy, and productivity. Shipment accuracy has increased to 99.9% across the network. Management visibility to inventory across the network is standardized with improved accuracy and provides Rinchem with the ability to quickly reposition inventory based on customer needs and reduce safety stock.

Chem-Star was conceived and developed based on the founder’s idea of a “Glass Pipeline” for end-to-end global supply chain logistics, providing the company and its customers with an integrated view of inventory and shipments for greater control and efficiency, such as coordination among links in the supply chain, facilitating reductions in safety stock, inventory obsolescence, and non-value adding activities.

Chem-Star incorporates Tecsys WMS and a leading transportation management system (TMS) which enables inventory visibility across Rinchem’s network of warehouses and transportation links. It utilizes GPS tracking for Rinchem’s customized, over-the-road fleet of tractor/trailer units to ensure visibility of customer loads. Chem-Star is available to customers 24/7 through a secured web-based interface that offers many different real-time inventory queries and reports.

With Chem-Star, Rinchem can host and/or interface with any customer ERP or inventory management system to increase visibility and seamless transition of data across the supply chain. Other features include:

Rinchem is following a 50/50 model to grow the company organically by extending its reach into customer verticals with strong growth potential and through acquisition, especially to expand its international presence in major markets.

Last year, Rinchem announced the formation of Rinchem International to organize and lead all non-US Rinchem customer service centers. This new Rinchem entity was formed to better serve international customers and enable international growth by providing stronger leadership and quicker decision-making abilities with a focus on local presence.

It expects ITM services to grow rapidly as an NVOCC, as well as to leverage lead logistics provider capabilities to increase domestic transportation management revenue and strategically place transportation assets in new markets.

The company views its emerging technology with Chem-Star as an important competitive differentiator in the market and will continue to expand its capabilities based on a solid foundation of logistics executional systems.

Sources: A&A Primary Research, https://www.rinchem.com